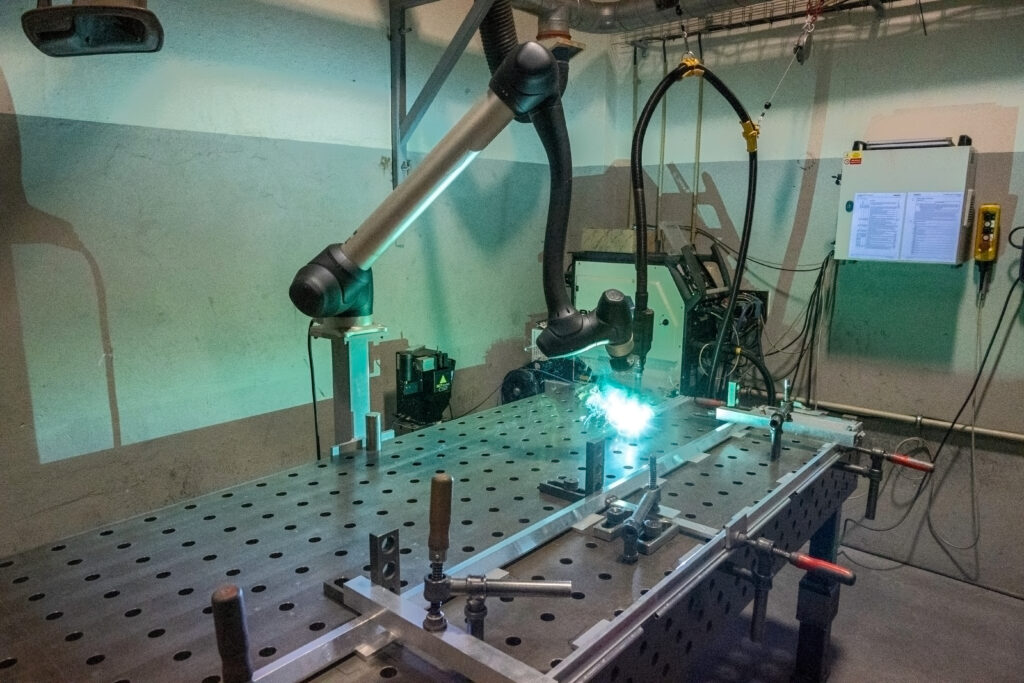

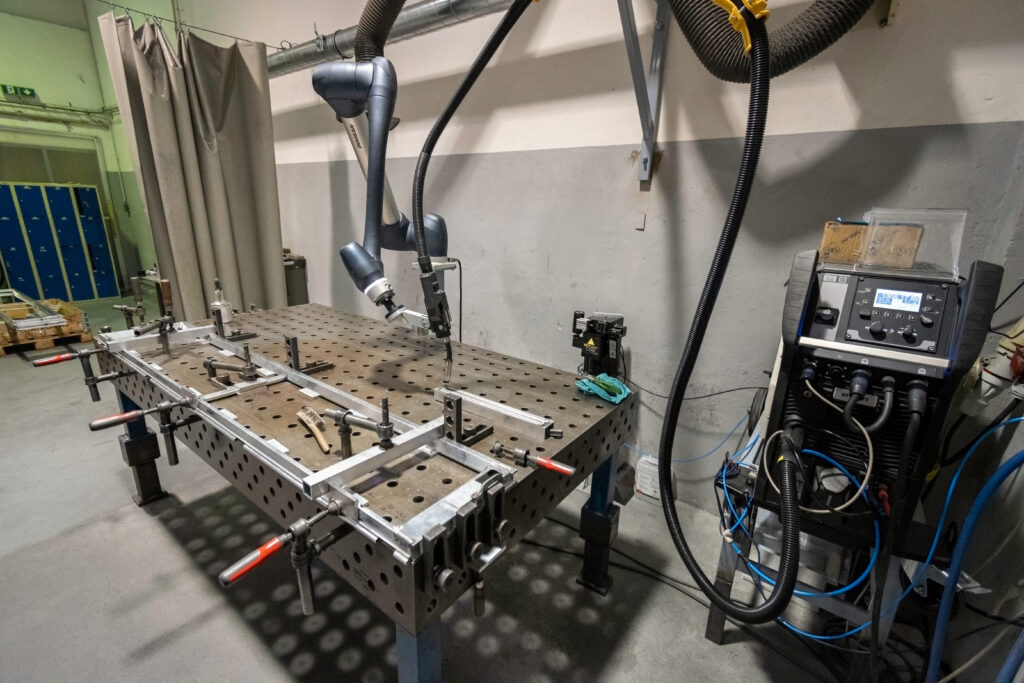

Robotic welding – efficiency and quality thanks to modern technology

Our investment in robotic welding includes the deployment of an advanced Doosan cobot in conjunction with an EWM welding power supply, enabling us to weld a wide range of materials efficiently and accurately.

- Welding method: MIG (131 according to EN ISO 4063)

- Materials:

- Aluminum alloys – welding combinations of 23.1 with 23.1, 22.1 with 22.1, 22.2 with 22.2, 22.3 with 22.3, 22.4 with 22.4, and also combinations between 22.1, 22.2, 22.3, 22.4 and 23.1, all qualified to WPQR (EN ISO 15614-2)

- Stainless steel materials

- Thickness of material to be welded: 1.5 to 40 mm for fillet welds

- Maximum weld dimensions: up to 2300 x 1400 x 1000 mm

Our certified operators (EN ISO 14732) and our possession of the certificates EN ISO 3438-2, EN 15085 CL 1 and ČD V 95/5 guarantee the highest quality and safety standards in welding processes. Thanks to this technology and expertise, we can meet the demanding requirements of our customers and offer reliable, efficient welding solutions.